Drainage Products

Stainless Steel Drainage Channel

Our background spans an extensive 30 years of experience in food, beverage, drink, dairy, brewery, and abattoir processing. Leveraging this knowledge, we’ve developed floor drain systems tailored for industrial and commercial applications where hygiene and reliability are paramount.

Stainless Construction

Available in grade

316 or 304

In-House Design

Custom design and shop drawings

Industrial Spec

High Load & Slip Ratings

High Temp Suitable

Wash down up to 200°C

Hygiene Design

HACCP and EHEDG Certified

Made in Australia

Channel made to your design

It's All In The Design

Engineered for hygiene, our channels are manufactured in Australia to your specifications. Featuring a range of grate options to choose from, our channels are based on 8x different design types for concrete, vinyl sheet floors, laundry surge or our round bottom H Type hygiene design.

Featuring the same benefits of the Floor Gully range, choice of Grate, Filter Basket, Removable Foul Air Trap (FAT) and Secondary Strainer to be selected for the outlet, yet easily removed for cleaning and access is standard.

The longest channel designed by our in house team is 110m long!

Experience and Expertise in Drainage Products

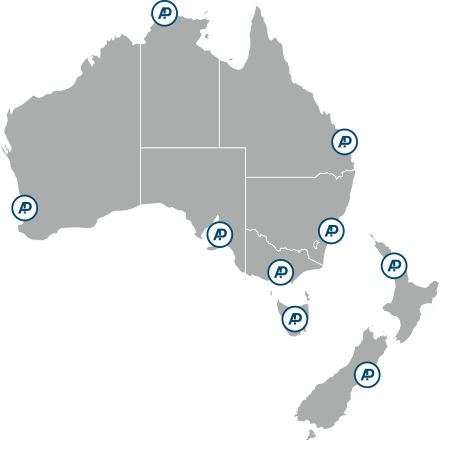

We were the first to supply stainless steel drainage into Australia and have supplied to projects large and small since 1992. We bring over 30 years of expertise in sectors like food, beverage, dairy, brewery, and abattoir processing. Using this experience, we’ve developed floor drainage systems suited for both industrial and commercial needs. Our products, including stainless steel channels and drains, emphasise hygiene and reliability.

Where to use?

Our drainage solutions are the go-to solution when hygiene, high temperature, and high performance are vital. Applications range from food, beverage, dairies, commercial kitchens, and supermarkets to breweries, abattoirs, medical facilities, pharmaceutical labs, and loading bays. They also include truck wash-down areas, as well as public and commercial spaces.

Why Choose AusPress Stainless Steel Drainage?

AusPress stainless steel drainage channels and grates are solid and heavy duty, ensuring they remain straight during transport and installation. They exhibit minimal expansion and contraction rates, much lower than other materials. Moreover, being fully recyclable and long-lasting, stainless steel is an eco-friendly option.

Our products boast reliability and key certifications including WaterMark, HACCP, and other Australian standards. They also have approval from various Australian State and Territory Water corporations. AusPress channels are compatible with cleaning chemicals and hot water, even at high temperatures. This makes them ideal for major food and beverage production facilities.

Recommendations and Support

Before specifying or installing, we always recommend checking for product suitability. We extend our support for verifying chemicals and other requirements. Just ask, and we are here to assist!

What Makes us the Leading Australian Stainless Steel Drainage Supplier?

With unparalleled experience and a broad offering, AusPress Drainage provides a dependable solution. We cater to trade waste, sewer waste, storm drain, and other drainage needs. Our product range includes grates and channels, paired with diverse design options. This versatility fits a wide range of industrial and commercial uses.

Our continuous commitment to quality and sustainability has made us a leading name in the industry. Trust AusPress with your drainage channels and experience the excellence that only we can deliver.

Quick Facts: |

|

Frequently Asked Questions

Where are they manufactured?

AusPress Stainless Steel Channels and Specialised drainage products are manufactured in Adelaide, South Australia and safely transported nationally.

How long do they take to manufacture?

Dependant on the project size, channel manufacture is approximately 15-20 working days from drawing approval. If it is a large project, we work with the plumber/builder and/or the facility on the building program schedule, to ensure successful, on time and in full supply

Why is 316 more expensive than 304?

316 Stainless Steel has an extra component (Molybdenum), which offers a much higher level of corrosion resistance. When considering the cleaning chemicals and harsh fluids that are flushed through the drainage systems, 316 Stainless Steel is a vital requirement for the channels, grates and components.

What’s the longest single channel length?

We typically stick to 6m sections in our manufacturing principles to enable ease of transport. These sections are then bolted together by means of flanges, gaskets, nuts and bolts to make as a channel as is needed for the facility. The longest channels AusPress has ever made was over 700 metres long.

Why use Stainless Steel? Other materials are cheaper

Stainless Steel is the only impervious, long term product, that can last the life of the building under normal operating conditions. As channels are typically installed and cast into the concrete floors, it is vitally important that they are made to last the lifetime of the building as they are very expensive to repair and replace when you consider not just construction costs, but oncosts to cease operation within the facility. It is part of the buildings structure, and must be able to perform to client expectations.

Can I connect existing drainage to the channel?

Yes. We can design a custom layout and adjust where an outlet is located along a channel, and create fall to the outlet, as long as the existing drainage is of size and complies to local regulations.

What’s the difference between your channels and others? Why is there a price difference

AusPress has more than 30 years’ experience in the industrial drainage market and has been manufacturing custom made Stainless Steel channels for more than 20 years in Australia. Through our experience, we only use the highest standards of materials and manufacturing techniques as we understand how expensive it is to repair or replace inferior products. AusPress industrial drainage channels are manufactured from minimum thickness of 1.5mm 316 Stainless Steel, for the rigorous environments they are installed in. All of our components such as grates, baskets and secondary strainers all meet stringent local requirements. They also comply to the highest of Australian standards, local government approvals and carry HACCP certification for food and beverage facilities to ensure the client receives exactly what is required for the project.

Can AusPress help design the drainage system?

Yes, AusPress has a highly experienced and professional technical design team to assist in client requirements. AusPress undertake full design drawings and produce all shop drawings in house. We quite often are asked to help with design, to ensure the correct outcome for the client. This can be in the form of Data sheets, or complete channel design to present to the client.

What channel options do I have? Why is one shape better than the other

We have several channel option designs, shape and design are usually related to where it is to be used, the facility type and what is expected to be transported or drained through the system.

- Standard V Base channel, most commonly used and requested channel, kitchens, production areas, usually low waste product on the floors.

- Slot channel, used where moderate fluid discharge on floor, used in wineries and beverage facilities, areas of very low waste product on floors.

- Hygiene channel, mainly used in food processing or production areas, can have higher volume of waste product, that requires higher volume of water for wash down to move product to waste points.

- HygieneMax Channel, best channel design for food processing or beverage facilities, direct product to base of channel, with lower volume of water washing down product to waste points.

- Flat base channel, common uses, stormwater, showers, threshold to doors, driveways.

Grates are matched up to channels, for application, and location.

How long will they last?

Stainless Steel channels are an investment for the client and are installed by being cast into the concrete making them part of the “skeleton” of the building. With correct maintenance, they will last or exceed the life of the building. This could be in excess of 50 years. This is a vital factor in determining your next channel as any replacement or rectification works to remove inferior channels requires a shut-down which can cost the facility much, much more than doing it right the first time.

What are stainless steel drainage channels used for?

AusPress Stainless Steel Drainage Channels are designed to suit each facility and location. From general drainage, spillage and washdowns, to cleaning chemicals, our channels are suitable for use in all food and beverage manufacturing facilities as well as loading docks and general ground drainage. Primarily, our channels are designed to keep production areas running and safe.

Can stainless steel drainage channels be used in outdoor applications?

Stainless Steel channels can and are widely used outdoors applications, care must be taken when in salt or chemical residue areas.

Are stainless steel drainage channels resistant to corrosion?

Stainless Steel Channels are corrosion resistant when in the correct environment.

Where can I purchase stainless steel drainage channels?

AusPress Channels can be purchased through Plumbing merchants affiliated with AusPress, or direct contact with AusPress, we can help.