Drainage Products

Stainless Drainage Pipe & Fittings

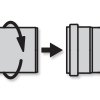

Installing stainless drainage is very fast and simple with the push fit join design requiring no priming, welding or glues to perform in high temperature and hygiene sensitive environments.

Small & Big Diameters

Available 50 – 315mm

Push to Join

No Welding or Gluing

Stocked in Australia

Ready for Dispatch

High Temp Suitable

Wash down up to 200°C

Hygiene Preferred

Grade 316L Stainless Steel

Made in Europe

Socket Pipe & Socket Fittings

Experience and Expertise in Stainless Steel Drainage Pipe & Fittings

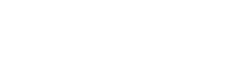

For more than 30 years, AusPress has been at the forefront of the stainless drainage industry, delivering reliable and efficient solutions to demanding environments. Introduced to the Australian and New Zealand markets in 1992, our vast experience sets us apart, with our solutions proving indispensable to sectors like food & beverage processing, commercial kitchens, and healthcare facilities.

Design and Construction

Our stainless drainage systems epitomise precision engineering. Utilising the socket and spigot architecture, each join boasts a temperature-rated rubber ring seal. This design advantage ensures that stainless steel undergoes minimal expansion and contraction, making it superior to plastics in stability. The inherent strength and chemical resistance of stainless steel, combined with our pre-fitted double lip ring seal, guarantees trouble-free sealing and exceptional performance.

Products and Range

AusPress offers a comprehensive range of stainless drainage pipes and fittings, designed to cater to varied needs. Available in diameters ranging from 50 to 315mm, our products are adaptable, reusable, and versatile. Whether you need polished finishes for visible applications like downpipes or under-sink traps or require specialised fittings for trade waste or vacuum sewer, our inventory has you covered.

Why Choose AusPress Stainless Steel Drainage Pipe & Fittings?

Our commitment to quality is evidenced by our products, bearing WaterMark, HACCP and DNV certifications. Moreover, AusPress stainless steel drainage systems stand out for their lightweight nature, ensuring ease of transport and installation. Additionally, the recyclability of stainless steel makes our products environmentally friendly, highlighting our dedication to sustainable solutions.

Recommendations and Support

Before embarking on any installation, we always advise our customers to verify product compatibility. We understand that every project comes with its unique challenges, and our team is on standby to assist with queries, be it related to chemical interactions, product specifications, or installation procedures. Your success is our priority.

What Makes us the Leading Australian Stainless Steel Drainage Pipe & Fittings Supplier?

AusPress’s journey, pioneering stainless drainage in Australia, underscores our leadership in the industry. Our commitment to excellence, from product design to customer support, sets us apart. Collaborating with facilities, consultants and installers on specialised projects and offering in-house design support, we ensure tailored solutions for each project. Combine this with our adherence to international standards, and it becomes evident why AusPress remains the preferred choice for many.

Quick Facts: |

|