Stainless Steel Press-Fit Systems

Stainless Steel Press-Fit for Compressed Air Systems

Clean, Safe, and Reliable Under Pressure Compressed air is the backbone of many industrial and commercial operations, and the performance of your piping system plays a critical role in maintaining efficiency, safety, and reliability. AusPress stainless steel press-fit systems offer a superior solution for compressed air delivery—outperforming traditional materials such as plastic, copper, and galvanised steel in durability, leak prevention, and long-term cost-effectiveness.

Material Comparison: Stainless Steel vs Alternatives

| Material | Pressure/Temp Resistance | Corrosion Resistance | Cleanliness | Installation Time | Durability |

| Stainless Steel | High | Excellent | Excellent | Fast (press-fit) | Long-term |

| Copper | Moderate | Good (except ammonia-rich) | Good | Requires brazing | Moderate |

| Galvanised Steel | Moderate | Poor (rust & scale risk) | Poor | Threaded, slow | Short-to-mid |

| Plastic (e.g. PVC, PE) | Limited | Good | Good | Easy, but limited | Variable |

| Aluminium | Moderate | Good | Good | Easy, system-specific | Mid term |

Why Use Stainless Steel Press-Fit for Compressed Air?

Compressed air systems demand strength, precision, and minimal leakage to operate efficiently. Stainless steel press-fit offers:

High Pressure & Temperature Tolerance

With excellent mechanical strength and thermal stability, stainless steel is ideal for compressed air systems operating under high pressure or elevated temperatures, unlike plastic systems which can deform or degrade over time.

Corrosion Resistance

Stainless steel’s natural resistance to corrosion ensures a long service life, even in humid or aggressive environments. This eliminates the risk of rust, internal scaling, or particle shedding often seen in galvanised steel and carbon steel systems.

Leak-Free Performance

AusPress press-fit systems use precision-engineered fittings with integrated O-rings, ensuring airtight joints without welding or threading—minimising pressure loss and increasing energy efficiency.

Clean, Oil-Free Operation

For industries requiring contamination-free air (e.g., food, pharmaceutical, clean manufacturing), stainless steel ensures a clean internal surface free of oils, coatings, or chemical leaching.

Fast, Flame-Free Installation

Press-fit technology enables quick and safe installations with no need for hot works, threading, or soldering—reducing downtime, labour costs, and WHS risks.

Ideal For:

- Manufacturing & fabrication facilities

- Food and beverage processing

- Laboratories and cleanrooms

- Automotive workshops

- Pharmaceutical plants

- Data centres and critical services

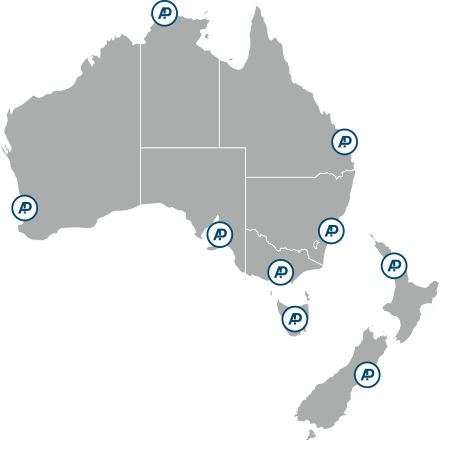

Why AusPress?

With decades of experience in stainless steel systems, AusPress is the trusted partner for compressed air projects across Australia. Our stainless steel press-fit range is certified, leak-tested, and designed for long-term reliability—no matter the industry or application.

Choose strength. Choose precision. Choose AusPress stainless steel for compressed air.

Whether you’re running hot or cold water, LPG or natural gas, AusPress stainless steel press-fit delivers the safety, speed, and strength your project demands.- Call us at 1300 AUSPRESS (1300 287 773)

- Or contact our team to request technical specifications or a project quote.