The benefits of Annealed Stainless Steel

Stainless steel has been popular since it was invented. As stainless steel materials have good properties like corrosion resistance and high strength, products made of stainless steel materials are widely applied in our life and industry.

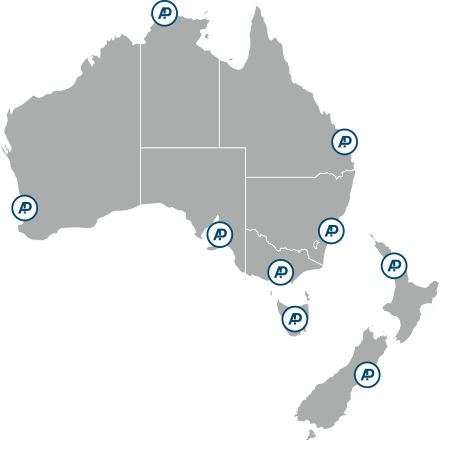

AusPress has been distributing Stainless Steel Press-Fit systems for more than 25 years and is arguably the most experienced company in Australia in this field. Knowing the risks and benefits of any system is a key responsibility of any manufacturer or distributor. AusPress understand that water quality can differ from state to state, town to town and suburb to suburb. The vast majority of any corrosion or pitting in stainless steel systems is caused by water quality, in particular the harshness of the water or the chloride levels. It is for this reason that 12 months ago, AusPress decided to move to fully annealed tube for our stainless steel press-fit system. Our annealed tube is now available in all sizes from 15mm to 168mm.

Annealing stainless steel is critical to certain applications where superior corrosion resistance is necessary. Generally, the more complex the alloy, the more difficult the annealing process (however, austenitic and some ferritic stainless steel types are easy to anneal). The process relieves the stresses of manufacturing and softens the steel down to a point where it can be more easily manipulated. It also improves ductility, which is a desired finished property for certain applications. Stainless steel tube annealing is an important production process and the heat treatment is carried out under controlled conditions to avoid carburisation, decarburisation and scaling on the metal surface. Unlike the annealing process of copper (where the copper tube becomes soft and permeable) the process used to anneal stainless steel (rapid heat and rapid cold) causes the tube molecules to relax along the weld line to aid in corrosion resistance, but the tube remains rigid and strong.

Stainless steel tube annealing is a solution treatment employed for recrystallising the work-hardened austenitic stainless steels and drawing chromium carbides. In addition, stainless steel tube annealing removes stresses that occur during cold-welding, and homogenises dendritic stainless steel welds which are a typical starting point for pitting corrosion.

With the vast majority of press-fit stainless tubes being TIG welded, as the tube is formed and welded, it leaves vulnerabilities in the welded joint which act as a major stress point. In simple terms, the annealing process relaxes these stress points and therefore offers a much higher level of corrosion resistance which further aids in a much higher level of pitting resistance.

The annealing process is completed by placing the finished tube into a furnace at a temperature of 1040°C, but certain types of steel can be annealed at the temperature below 1010°C. This high temperature is required to ensure a brighter appearance. Heating is done as fast as possible as slow heat will result in oxidation.

completed by placing the finished tube into a furnace at a temperature of 1040°C, but certain types of steel can be annealed at the temperature below 1010°C. This high temperature is required to ensure a brighter appearance. Heating is done as fast as possible as slow heat will result in oxidation.

After the treatment, the hardness can be enhanced and the metallic luster can be maintained. Stainless steel tube annealing helps to improve the quality and pitting corrosion resistance. In addition to the annealing process, there are also other production processes. For example, there are processes like quench annealing, hardening, cooling and stress reliving. Different processes are aimed to strengthen the certain properties of the stainless steel tubes.

When completing your next project, ensure you use the highest quality products available to ensure a low maintenance and long life installation. Speak to your local AusPress representative for more information.

0 comments

Write a comment